You want Tampa cleaning professionals who demonstrate trust. Require OSHA/CDC-aligned SOPs, EPA List N chemicals, and ISSA/GBAC or CIMS-GB frameworks. Check background checks, identity, and annual re-screening with access-level badges. Insist on certified training, bloodborne pathogen and HazCom modules, pass/fail audits, and ATP-based QA with defect and rework trends. Anticipate real-time timestamps, photos, and corrective-action windows. Request flat-rate, itemized scopes, SLAs, and insured compliance. Eco-safe HEPA systems and calibrated dilution minimize risk, cost, and disruption-here's how to choose confidently.

Primary Takeaways

- OSHA 1910/1926-certified, GBAC/ISSA-compliant teams with verified certifications, security clearances, and annual re-evaluation for reliable Tampa premises access.

- Carefully documented SOPs, QA evaluations, ATP testing, and timestamped photo evidence provide consistent, audit-ready results across all Tampa locations.

- Staff competency confirmed with onboarding validation, annual training updates, pass/fail audits, and mentorship tracking decreasing error rates over time.

- EPA List N approved chemicals, SDS accessible in 10 seconds, microfiber with color-coding, and closed-loop mopping minimize cross-contamination and risk.

- Occupancy-based scheduling, established SLAs, and live dashboard updates reduce disruption while achieving measurable cleaning objectives.

How Credibility and Consistency Impact Commercial Cleaning

Prior to comparing prices, you should evaluate a cleaning partner's reliability and dependability because they directly affect health outcomes, regulatory compliance, and operational uptime. You're accountable for metrics: incident rates, audit scores, absenteeism, and downtime. Reputable providers display third-party certifications, background checks, safety training completion rates, and verifiable references. They also publish SOPs, QA inspection frequencies, and corrective-action timelines.

Expect Steady results backed by data: compliance trends, ATP values, and chronologically marked checklists. Demand service-level commitments, not promises-reaction periods, re-clean thresholds, and escalation paths. Solid documentation protects you during compliance checks and claims. Consistency creates Client trust, minimizes variability risk, and stabilizes your operations. When vendors monitor, report, and improve, you decrease exposure, forecast costs accurately, and keep operations running.

Key Services That Every Tampa Cleaning Company Should Offer

You must have a cleaning partner that organizes daily and nightly janitorial tasks based on occupancy patterns, tracks completion rates, and flags exceptions. Match that with floor care and maintenance using surface-specific methods (e.g., VCT, carpet, terrazzo) and measurable outcomes like gloss readings and lifespan extensions. Additionally, demand disinfection and high-touch cleaning mapped to traffic heatmaps, validated with ATP testing, and calibrated to decrease pathogen risk.

Daily and Night Janitorial

Reliably executed daily and nightly janitorial keeps Tampa facilities compliant, safe, and presentable by adhering to a established checklist and schedule. You define measurable targets-touchpoint disinfection frequency, restroom resets per shift, waste stream accuracy-and inspect them each week. With precise shift scheduling, you avoid coverage gaps, align service windows to occupancy peaks, and control overtime risk. You'll implement SOPs for restrooms, breakrooms, offices, and high-traffic corridors, recording completion times and exceptions.

Utilize EPA-registered chemistries, color-coded microfiber, and closed-loop mopping to minimize cross-contamination. Implement equipment rotation to lengthen asset life and decrease downtime; track hours on vacuums and autoscrubbers, then schedule preventive maintenance. You log incidents, spill responses, and missed services, then conduct root-cause analysis. This decreases complaints, enhances IAQ, and supports OSHA and CDC guidance.

Floor Care and Maintenance

Preserving floors through a defined care program reduces slip risk, extends asset life, and preserves brand image. You begin with a site audit: traffic counts, soil loads, floor types, and finish condition. From that data, we develop a schedule that sequences routine dust control, scheduled machine scrubbing, and periodic restoration.

With sealed concrete, you use pH-appropriate detergents, inspect film integrity quarterly, and re-seal depending on gloss meter readings and water-drop tests. For polished terrazzo surfaces, you sustain shine through diamond pad honing and measured RPM burnishing, measuring coefficient of friction to meet ANSI standards.

You control risk by positioning walk-off matting at 15 linear feet minimum, maintaining spill response times below five minutes, and tracking each service with pictures, meter readings, and corrective actions.

High-Touch Area Disinfection and Cleaning

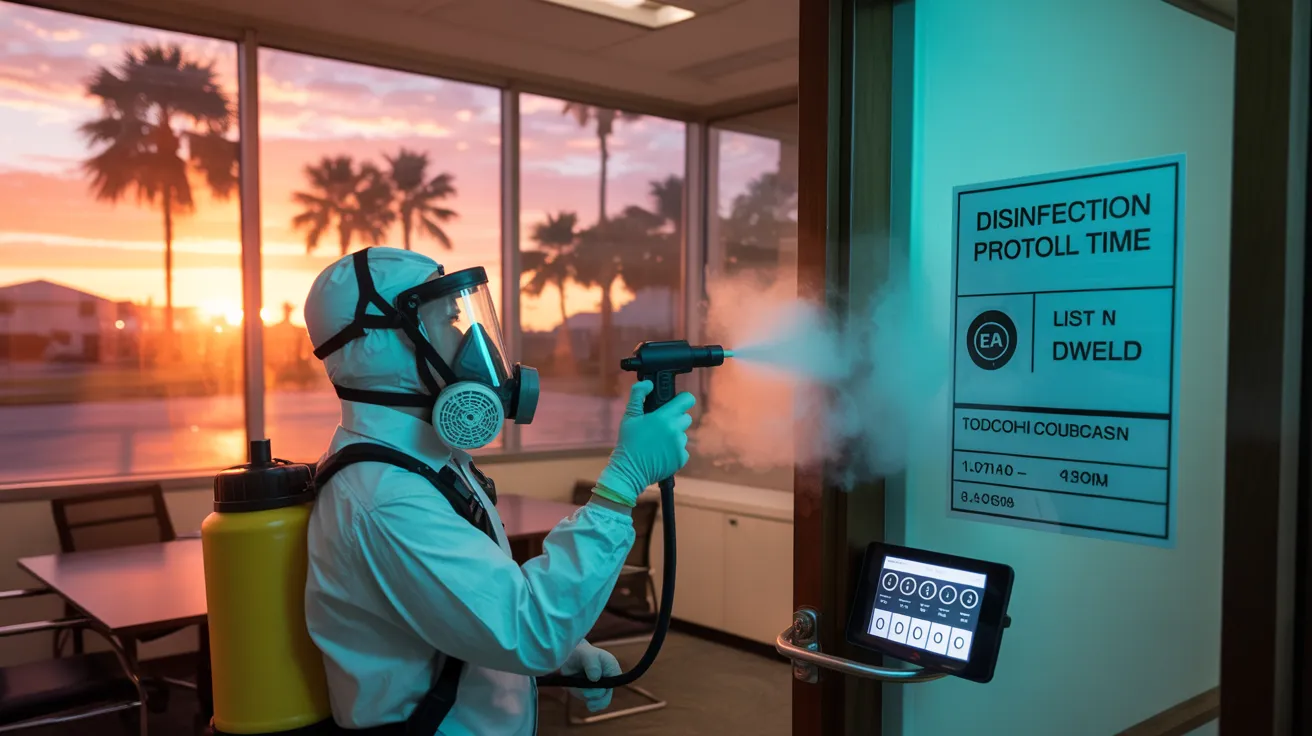

While pathogens fluctuate seasonally in Tampa's humid climate, frequently contacted surface disinfection demands a standardized, measurable program. You commence by establishing risk zones through surface mapping, then classify touchpoints-door hardware, railings, elevator buttons, POS terminals, breakroom fixtures-by frequency and user density. Employ contact audits to quantify touches per hour and set cleaning intervals. Validate product choice: EPA List N, appropriate dwell times, and material compatibility to here avoid corrosion.

Implement consistent protocols: clean debris first, apply disinfectant, ensure complete dwell period, and implement color-sorted textiles to avoid contamination spread. Synchronize routines to busy intervals and modify based on inspection results. Confirm results with ATP testing, targeted audits, and tracking reports. Train staff, track lot numbers, and document every pass, so you cut transmission risk and establish protocol compliance.

Specialized Industry Knowledge: Offices, Medical, Retail, and Restaurants

As each facility type presents distinct risks and regulations, you must have a cleaning partner that adapts methods, chemicals, and verification to your environment. We commence with client onboarding that charts square footage, traffic patterns, and risk zones, then coordinate schedules to your staff workflows.

Within office environments, we emphasize allergen reduction, sensor-verified restroom schedules, and night-shift dust control to maintain equipment uptime. For medical suites, we separate clean/dirty corridors, color-code implements, and log dwell times to reduce cross-contamination risk. Retail demands fast-turn floor care, point-of-sale disinfection, and backroom degreasing that doesn't interfere with merchandising. Restaurants require grease-load indexing, hood-adjacent detail, and ATP spot checks that validate food-contact surfaces before opening.

You receive documented tasks, photo timestamps, exception alerts, and continuous improvement reviews that tighten outcomes over time.

Expected Cleaning Standards, Certifications, and Compliance

You should verify that your provider complies with industry-standard protocols (such as ISSA/GBAC, CDC/EPA guidance) with documented SOPs and measurable QA checks. Prioritize safety and compliance by confirming OSHA adherence, chemical SDS management, and EPA-registered disinfectant use documented by lot and dwell time. Demand certified staff training with verification of onboarding, annual refreshers, and competency audits connected to incident and corrective-action logs.

Industry-Level Standards

Even before you compare prices, confirm that a Tampa commercial cleaner meets recognized standards and can demonstrate compliance. Ask for written SOPs mapped to ISSA/GBAC and CDC guidelines, plus evidence of protocol audits performed at defined intervals. You should see task frequencies, dwell-time benchmarks, validated chemistries, and equipment calibration logs. Insist on training completion rates, pass/fail scores, and corrective actions documented within 48 hours.

Ensure they monitor regulatory updates and modify SOPs within set SLAs. Examine chain-of-custody for chemicals, dilution verification, and lot traceability. Require zone-based workflows to stop cross-contamination, with color-coding and tool segregation. Evaluate QC benchmarks: ATP thresholds, defect rates, rework percentages, and trend reports. Finally, mandate third-party certification status, audit summaries, and measurable KPIs aligned with your site's risk profile.

Compliance and Safety

Though budget constraints prompt shortcuts, safety standards and regulatory adherence define the baseline for acceptable performance in Tampa commercial cleaning. You need confirmed alignment with OSHA, EPA, and local code: SDS availability within 10 seconds, chemical dilution logs, and documented incident rates below industry benchmarks. Expect clear hazard signage deployed before, during, and after tasks, plus lockout/tagout compliance for equipment.

Insist on a written compliance matrix linking tasks to standards (including bloodborne pathogens, slip-fall controls) and a chain-of-custody for disinfectants with EPA List N verification. Insist on scheduled PPE audits-fit testing, replacement cycles, and exception reporting-so gaps don't linger. Demand waste segregation logs, ventilation checks for aerosolized products, and post-service compliance summaries. Your vendor should supply corrective-action timelines within 24 hours when deviations are detected.

Accredited Staff Education

Since certification demonstrates competence, require crews trained and current on recognized standards: OSHA 1910/1926, EPA disinfectant use (List N), CDC healthcare cleaning, and ISSA/GBAC or CIMS-GB frameworks. Ask for proof: completion dates, refresher intervals, and pass rates. You're purchasing risk reduction, so validate bloodborne pathogen, hazard communication, and respiratory protection modules.

Require a documented training pipeline: baseline skills assessment, gap analysis, hands-on labs, and audited checklists. For food service or healthcare sites, ensure terminal-clean protocols and ATP verification targets. Insist on chain-of-custody for chemicals

Continuous proficiency is essential. Mandate quarterly drills, surface-material compatibility tests, and supervisor accompaniment using evaluation rubrics. Effective mentorship programs should connect certified leads with new techs, track error rates, and show declining incident rates over time.

Staff Management, Training, and Background Screenings That Build Trust

Before a single mop hits the floor, you need a thoroughly screened team, a documented training pipeline, and audit-ready background checks that minimize risk. You start by outlining role profiles, then source candidates with verifiable work histories. You conduct reference checks and identity verification, followed by county, state, and federal criminal screens. You establish eligibility to work and assess cultural fit to minimize turnover.

Your training program standardizes results: OSHA essentials, chemical processing, equipment calibration, surface-spec protocols, and incident reporting. Each module features pre and post assessments, skills checklists, and sign-offs archived in a secure LMS. Supervisors complete observed competencies at 30-day, 60-day, and 90-day intervals.

You copyright chain-of-custody for screening results, re-screen annually, and maintain access-level badges. The result: reliable performance

Scheduling, Communication, and Quality Oversight Without Interruption

Establish operations with a rhythm that adapts to your building, not vice versa. You establish service windows; we align crews with Flexible Scheduling constructed from occupancy data, traffic patterns, and event calendars. We chart zones, specify SLAs, and sequence tasks to provide Minimal Disruption to occupants and income operations.

Leverage Live Communication to retain control. You'll see date-stamped check-ins, completion photos, and incident flags in a shared dashboard. Discrepancies trigger corrective actions within defined response thresholds.

Our quality control follows a systematic approach: KPI scorecards, digital inspections, and trend analysis. We measure touchpoint frequency, turnaround times, and defect rates. Predictive Maintenance cues deep cleans or consumable replenishment before issues emerge. The result: reduced callbacks, reliable results, and a cleaning program that adapts as your building's demands change.

Sustainable Materials, Gear, and Protection Procedures

Having established scheduling, communication, and QA protocols, we apply the same rigorous approach to sustainable products, equipment, and safety. You get Green certification standards baked into every step. We evaluate plant based solutions through SDS reviews, surface compatibility tests, and ATP hygiene measurements. Data drives selection: dwell times, kill-claim scope, and residue scores must satisfy benchmarks without VOC spikes.

Our strategy for equipment reduces danger and waste. HEPA 13 vacuums trap 99.95% of particles; microfiber systems reduce chemical usage by up to 90%. Battery scrubbers employ controlled dispensing to prevent wet surfaces and slips. We calibrate dilution with color-coded stations and verify ppm on a weekly basis.

Safety measures are absolute requirements: GHS labeling, sealed-loop containment systems, PPE by task, lockout/tagout for machinery, and incident audits that drive corrective actions.

Clear Pricing, Agreements, and Service Level Agreements

While cleaning performance matter, your risk profile and budget control hinge on transparent pricing, clear contracts, and measurable SLAs. Require an itemized scope connected to a flat rate, not ambiguous hourly ranges. Require frequency, square footage, task lists, and consumables to map to line-item costs. Establish response times, quality thresholds, and corrective-action windows in the SLA, with credits for misses.

Specify change-order protocols, escalation channels, and proof-of-service: time stamps, geo-tagged check-ins, and audit checklists. Mandate renewal provisions, a clear cancellation policy, and caps on annual increases. Check insurance limits, indemnification, and background-screening attestations. Monitor KPIs monthly: defect rate, rework percentage, incident reports, and uptime for high-traffic zones. By implementing this system, you will minimize variance, avoid scope creep, and safeguard cash flow.

How to Screen, Compare, and Onboard Your Ideal Tampa Cleaning Partner

Before narrowing down vendors, determine your evaluation benchmarks and risk elements so you can examine Tampa cleaning firms against concrete evaluation points. Quantify needs: facility size, foot traffic flow, regulatory standards, financial limits, and turnaround expectations. Run structured vendor interviews with consistent question frameworks on worker allocation, supervisory systems, resources, and fallback arrangements. Insist on reference verification emphasizing comparable properties, past performance records, and quality assurance results. Compare proposals using ranked measurement indicators: issue occurrence, completion efficiency, evaluation outcomes, and remediation timelines.

Pilot with scoped trial periods to validate staffing stability, safety practices, and cost adherence. Define service targets and audit intervals before final approval. Use an onboarding checklist: background screenings, location introduction, security guidelines, hazardous materials/MSDS, authorization systems, and reporting templates. Measure weekly performance indicators and schedule a 30-day evaluation to validate compatibility.

Frequently Asked Questions

Is It Possible to Get Emergency Cleanup Within Two Hours of a Spill or Incident?

Yes. You'll receive emergency cleanup within two hours, supported by a rapid response protocol. We triage your incident, dispatch a certified team, and show up with OSHA-compliant PPE and EPA-registered agents. We conduct site assessment, containment, biohazard mitigation, removal, and surface decontamination, then confirm results with ATP testing. You'll get timestamped documentation and a risk report. If access, power, or permits hinder arrival, we escalate resources and supply ETA updates every 15 minutes.

Are You Offering Cleanup Services After Events for Trade Shows, Conferences, or Grand Openings?

Absolutely. You get post-event cleanup for conferences, trade shows, and grand openings. Envision floors gleaming before the last banner drops. We follow a checklist-driven process: debris sweep, waste segregation, hard-floor scrubbing, carpet extraction, restroom reset, and touchpoint sanitizing. We handle post event staging, vendor coordination, and loading-dock timing to minimize delays. You'll get time-stamped reports, QA photos, and incident logs. We mitigate risks via insured crews, OSHA-compliant chemicals, and equipment redundancy.

How Are Access Keys, Alarms, and Building Security Protocols?

You are provided with a thoroughly documented, risk-aware process for authorization keys, notification systems, and safety protocols. We establish key management with individual IDs, sign-out logs, and oversight audits. For alert integration, we coordinate access codes, entry windows, and escalation trees, after which we test procedures before service. Personnel complete background checks and site-specific training. We use geofencing check-ins, time-stamped photos, and incident reports. Occurrences activate cause analysis and corrective measures. You have oversight through scheduled reviews.

Is It Possible to Have the Same Cleaning Team Every Time?

Yes-you can request the same cleaning team for every visit. We prioritize consistent teams to accommodate client preferences, reduce variability, and improve quality metrics over time. We schedule your team as the default assignment, monitor attendance, and establish backups trained on your site notes to prevent disruptions. You'll receive documented processes, checklists, and performance KPIs. If staffing concerns develop, we notify you, present solutions, and maintain continuity through standardized procedures.

What Is Your Policy for Handling Lost or Damaged Items?

Similar to a carefully planned route, you'll submit documentation within 24 hours; we'll record all information, commence insurance validation, and start the claims handling process. You'll receive a written timeline, photos, and findings for full clarity. If we determine culpability, we deliver compensation within stated compensation limits. We reinforce employee accountability with audits, access logs, and retraining. You'll get status updates at each step, and we finalize all cases with risk mitigation protocols to decrease future exposure.

Closing Thoughts

It's time to pick a Tampa cleaning partner that's demonstrated, not merely claimed. Examine data: certifications, incident rates, QA scores, response SLAs, and audit logs. Validate processes: checklists, SOPs, training hours, and background checks. Mitigate risk: OSHA/CDC compliance, chemical SDS, and insurance limits. Insist on fit: sector expertise, off-hour scheduling, and eco-safe products. Assess apples-to-apples pricing and measurable KPIs. Then pilot, inspect, and iterate. With the right partner, your facility functions as a finely-tuned system-precise, consistent, and trusted.